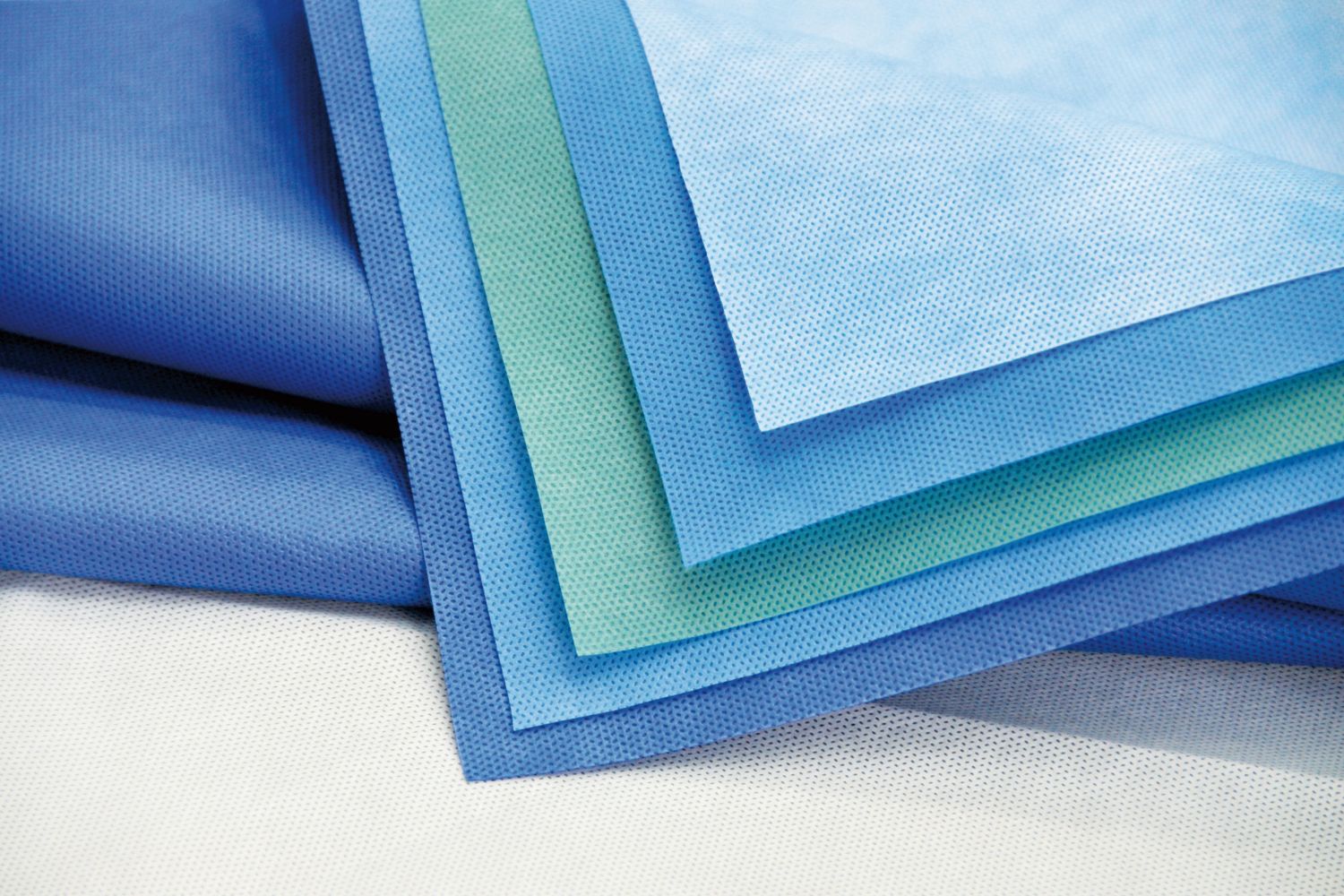

Medical-grade SSMMMMS/SMMMS/SSMMS nonwoven fabric features a unique multi-layer spunbond/meltblown composite structure, offering both high barrier properties and excellent breathability. Suitable for medical and protective products, it provides safety for healthcare workers and patients.

Multi-layer SMS (SSMMMMS/SMMMS/SSMMS) is used for surgical gowns and drapes.

Fabric Applications: Multi-layer SMS (SSMMMMS/SMMMS/SSMMS) nonwoven fabric can be used to manufacture surgical drapes, surgical gowns, cleanroom garments, and other medical products. It is suitable for steam, EtO (ethylene oxide), and low-temperature plasma sterilization and is compatible with product labels and sterilization indicator labels.

EN 13795/YY 0506: Multi-layer SMS (SSMMMMS/SMMMS/SSMMS) medical nonwoven fabric meets the performance requirements of EN 13795:2019 and YY/T 0506:2019 standards.

ANSI/AAMI PB70:2012

Multilayer SMS (SSMMMMS/SMMMS/SSMMS) nonwoven fabric meets the requirements of ANSI/AAMI PB70:2012 Level 1-Level 3 standards.

Biocompatibility

Multilayer SMS (SSMMMMS/SMMMS/SSMMS) nonwoven fabric has passed biocompatibility testing. Test results show that the product is non-toxic, non-allergenic, and does not irritate the skin.

Multi-layer SMS (SSMMMMS/SMMMS/SSMMS) for Sterilization Wrapping

Applications

Suitable for wrapping medical products requiring sterilization, such as medical tool kits and fabrics. Suitable for steam, EtO (ethylene oxide), and low-temperature plasma sterilization, and compatible with product labels and sterilization instruction labels. Proper use of the wrapping maximizes the cleanliness and sterility of medical supplies before use.

Biocompatibility Information

Multi-layer SMS (SSMMMMS/SMMMS/SSMMS) sterilization wrapping has been proven through biocompatibility testing to be non-toxic, non-irritating to skin, and non-allergenic nonwoven fabric.

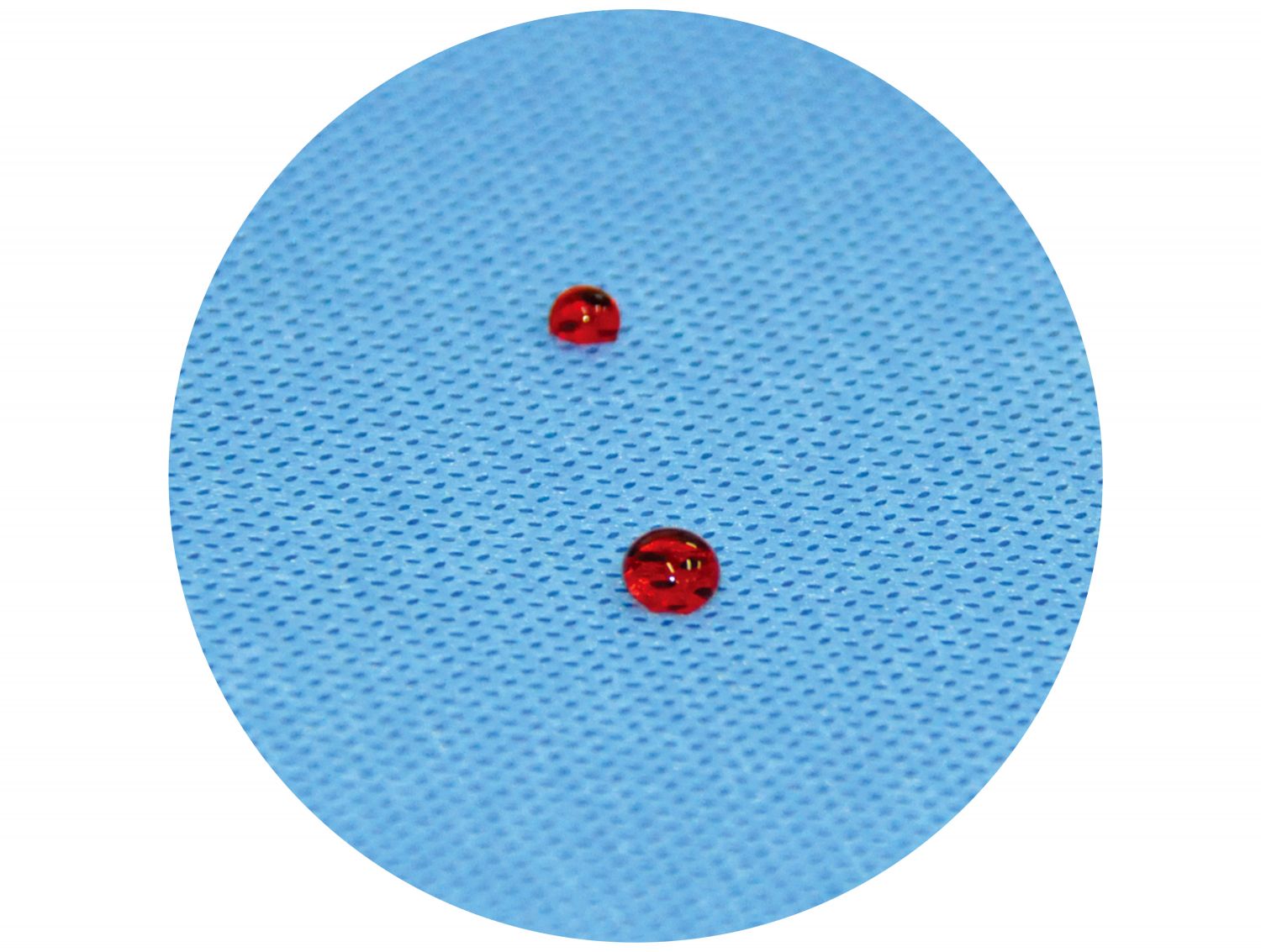

High Barrier Properties

The sterilization wrapping exhibits excellent hydrostatic pressure resistance and particle barrier properties.

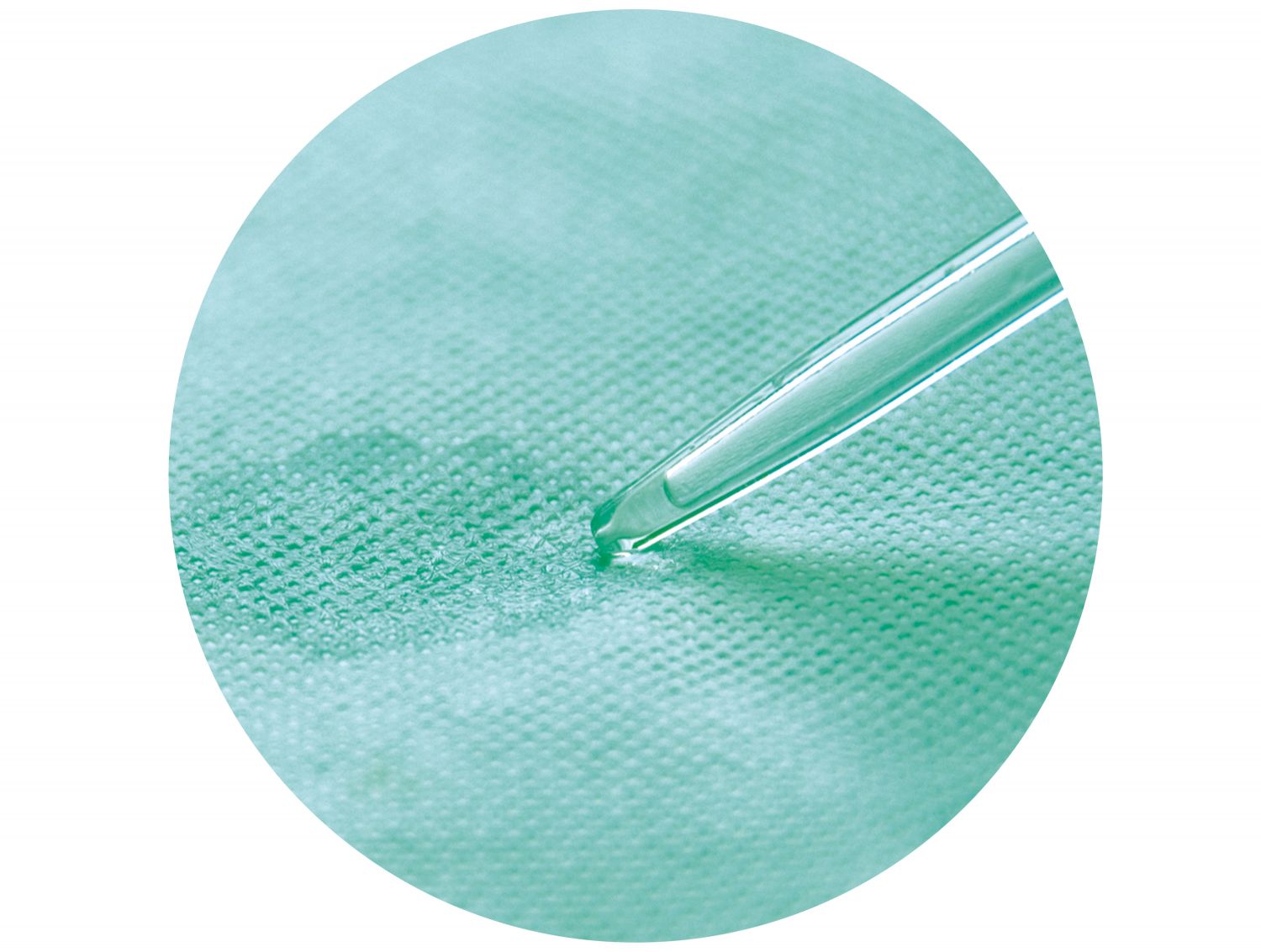

Good Breathability

The sterilization wrapping also possesses good breathability, making it suitable for ethylene oxide and steam sterilization.

Low Shrinkage

The sterilization wrapping features low shrinkage.

Excellent physical properties

The sterilization wrapping has good tear resistance and puncture resistance.

Nonwoven Fabric Finishing

**Three-Resistant + Antistatic Finishing**

Through three-resistant and antistatic finishing, the finished nonwoven fabric possesses alcohol-resistant, blood-resistant, oil-resistant, and antistatic properties. The treated nonwoven fabric meets the requirements of EN13795:2019, YY/T0506:2019, and ANSI/AAMI PB70:2012 Level 1-Level 3 standards. It can be used in surgical gowns, isolation gowns, surgical drapes, and cleanroom garments.

**Antistatic Finishing**

Mainly used in industrial, medical, and protective equipment.

**Absorbent Finishing**

Mainly used in absorbent materials for the surface layer of medical consumables, such as surgical drapes; also applicable to disposable wet wipes.

**Flame-Retardant Finishing**

Widely used in furniture and aerospace products, and has passed the testing of British Standard BS5852: Schedule 4 Part I & Part II and Schedule 5 Part I & Part III.

Antibacterial, deodorizing, and photocatalytic finishing

Primarily used in household products.

Fragrance finishing

Used in hygiene products (mint, lemon, lavender, etc.)

Composite Nonwoven Fabrics

Professional laminating equipment can bond different materials in two or more layers using methods such as spraying, coating, ultrasonic bonding, and lamination. This produces products with a variety of functional combinations, such as high strength, high absorbency, high barrier properties, and hydrostatic pressure resistance.

These composite materials are widely used in medical and hygiene products, protective clothing, industrial protection, and automotive industries.

SF - Nonwoven Fabric + Breathable Membrane

SFS - Nonwoven Fabric + Breathable Membrane + Nonwoven Fabric

◆ Two-layer/three-layer composite materials SF/SFS are our company's patented products, mainly used in surgical gowns, surgical drapes, protective clothing, and car covers.

◆ Protective clothing has been certified by the National Medical Products Administration and complies with GB 19082:2009 "Technical Requirements for Medical Disposable Protective Clothing".

◆ Composite fabrics meet the requirements of European standards Type 4B/5B/6B.

| NO. | Full Width | Description | Production Capacity | Features | Applications |

|---|---|---|---|---|---|

| 1 | 1.6/2.4m | Spray Adhesive Laminating Line | 150/300MT/month | Can perform 2-3 layers of lamination at one time | Protective clothing / Surgical drapes / Isolation gowns / Surgical gowns |

| 2 | 1.6m | Ultrasonic Laminating Line | 150MT/month | Dot embossing | Reinforcement patches for surgical drapes |

| 3 | 1.6m | Coating Laminating Line | 400MT/month | For 2-layer coating lamination | Protective clothing / Isolation gowns / Surgical gowns |

Send Inquiry